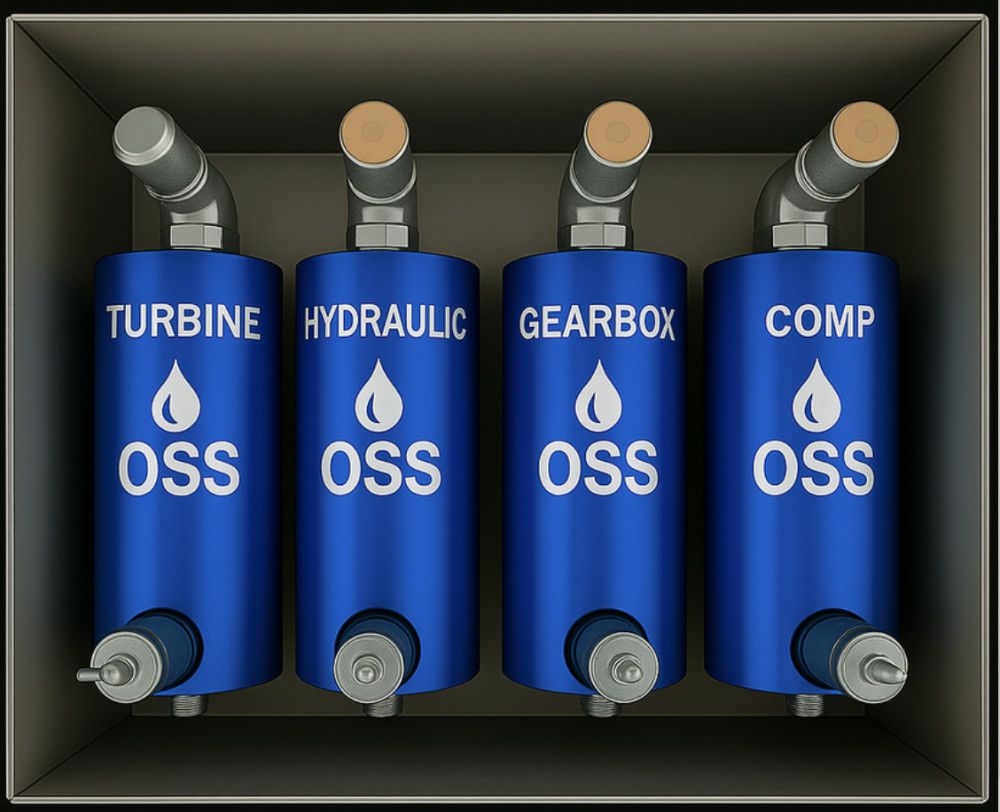

Oil Sampling Solutions for Refineries & Fixed Plants

Live Oil Samplers

The first standardized system for offline oil sampling that safely captures a live accurate fluid sample without exposing personnel to the line of fire or the operator or technician to any fluid pressure.